Welcome to kashibiology.com. In the previous post we have learned about the role of microbes in household products as well as different fermented products.

In this post we will learn about the next topic of our syllabus that is-role of Microbes at industrial or commercial level in the production of different types of important chemicals such as alcohol production.

Microbes in Beverage industry

A number of microbes are being used in alcohol production at the commercial scale.

On the basis and the type of raw material and the type of microbes, different types of beverage are produced after fermentation.

The most common microbes used in the fermentation process are the fungus Saccharomyces cerevisiae (Yeast) and its other species.

It was Louis Pasteur who first reported that beer and buttermilk are produced due to the microbial activity of yeast or yeast like organisms.

At present time a number of yeast species use in production of alcohol in fermentation processes.

Species of Yeast used in Alcohol Production

The most common is Saccharomyces cerevisiae also called Brewer’s yeast. Other species of yeast used commercially are-

Saccharomyces ellipsoidens called wine yeast.

Saccharomyces sake, also known as sake yeast.

Saccharomyces pireformis called Ginger yeast

Raw materials in Alcoholic fermentation

The raw materials for different types of alcoholic fermentation also vary.

Such as the nutrient media for beer is Barley malt.

Gin is produce by fermented rye malt.

For sake the raw materials is fermented rice.

Similarly for fenny, cashew and Apple is raw material.

Vodka is produce by potato.

In whisky fermented cereals is used.

Fermented molasses used in Rum production.

For wines and brandy fermented juices of fruits are used.

Process of fermentation

Yeast alone is not able to carry out the overall fermentation process at commercial level due to insufficient production of amylase enzymes.

Therefore one percent of malt or another fungus Rhizopus is also used. if the nutrient medium consists of complex carbohydrates which are present in raw material, like cereals and potatoes.

The hydrolysis of starch takes place in a different tank at a somewhat high temperature which is about 55 degrees Celsius for 30 minutes.

Then after the crushed food mix with hot water to obtain malt. This process of obtaining the product is called mash.

Before the alcoholic fermentation the nutrient medium is sweetened this is called wort.

After formation of nutrient medium or wort it is transferred into large tanks also called fermenters.

Before transfer of nutrient medium into fermenters, it should be sterilized with the help of steam under pressure. Then left for cooling

After the cooling of liquid nutrient medium or wort, it is introduced by a strain of yeast.

In a suitable environment the yeast starts the fermentation and ultimately produces alcohol.

Types of culture used in Alcohol Productions

The overall fermentation process at commercial level can be carried out by following ways.

Batch culture processes

In this process large bioreactors or fermenters are used. These fermenters has capacity of about 225000 liters or more of the nutrient media

The process of fermentation continues working, till the maximum alcohol content is achieved. It is called the wash.

The same is removed and the tank is ready for next batch after sterilization

Fed batch culture process

In this process small quantity of growth media is continuously introducing fermenters therefore microbes formatting the nutrient media without any inhibition

Continuous culture process

In this process the amount of fermented products or alcohol has been removed and action of more liquid media in the fermenters or bioreactor.

Immobilized Yeast fermentation process

This is the more efficient technique for alcoholic fermentation and produces 20 times more alcohol as compared to other techniques.

In this the Yeast is immobilized in calcium alginate beads.

Biochemical reactions in Fermentation

Fermentation is commonly found in the presence of organisms such as fungi and bacteria.

The fungus, Yeast can respire both in aerobic condition as well as in anaerobic condition.

In an anaerobic respiration, it Shows Fermentation and therefore the end product is the alcohol.

The process of fermentation takes place in the following steps.

First step-

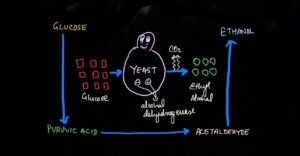

In the first step glucose breaks down into 3 carbon compounds called Pyruvic acid by the process of Glycolysis.

The process of Glycolysis takes place in the cell cytoplasm of all the cellular organisms other prokaryotes or eukaryotes.

Glycolysis is the common respiratory pathway in both aerobic and anaerobic respiration. The end product is Pyruvic acid or Pyruvate.

When Pyruvate enters in anaerobic process it is converted into alcohol or if the oxygen is present it will enter in mitochondria where it is completely oxidized by Krebs cycle.

Second step-

In the second step Pyruvic acid is converted into acetaldehyde.

This process take place in the presence of enzyme Pyruvate Decarboxylase with the release of carbon dioxide.

Enzyme Pyruvate decarboxylase performs decarboxylation that is release of a carbon dioxide molecule from the three carbons molecule of Pyruvic acid resulting in two carbons molecule acetaldehyde is formed.

Third step-

Now in the third step acetaldehyde is changed into ethyl alcohol or ethanol in the presence of enzyme alcohol dehydrogenase.

In this process the hydrogen ion is needed which is provided from reduced NADH.

Conclusion

In this post we have learned about the process of fermentation at commercial level as well as, what is the exact biochemical process behind the fermentation process in naturally occurring organisms such as fungi and bacteria.

From the above it is clear that a number of microbes are very useful in production of different types of important chemicals such as alcohol.

We also know that alcohol is not only used in beverage production or different types of alcoholic drink production but also used in making different types of medicines, in spotting as well as various processes in the laboratory.

In the next post we shall discuss the role of microbes in antibiotic production in detail.

Hope you will understand the concept of fermentation and role of microbes in alcohol production.

If you have any suggestion or found any mistake in the post please update us by comment.

Thanks for reading this post.